Straightpoint load cells making the construction industry a safer place

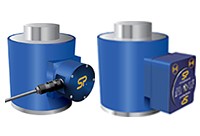

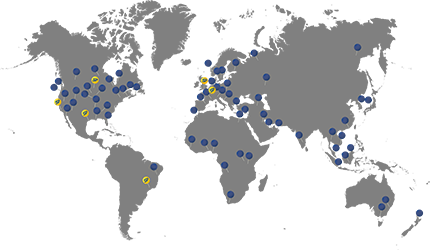

The Straightpoint range of wireless tension and compression Loadcells connected to our impressive range of handheld displays, multi Loadcell data logging or centre of gravity software are used throughout the worldwide construction industry on a daily basis.

When shoring or propping columns, ackrows and beams on construction projects require dynamic load measurement Straightpoint wireless compression loadcells and loadpin solutions lead the way in accurate and reliable measurement and can feed back to a multitude of instrumentation and software for real time and datalogged audit trails.

Tower cranes weighing materials with a digital dynamometer, compression Loadcells to monitor piling loads, testing of reinforced steelworks or real-time monitoring of building load distribution are all applications that Straightpoint can offer a load monitoring solution.

Need a price? Contact our team

Product Recommendations:

Radiolink plus Load Cell | Cable Compression Loadcell | Wireless Load Shackle | INSIGHT Software

Extreme Sports

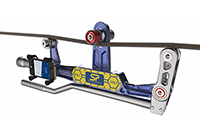

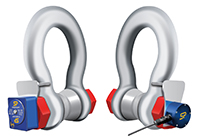

Adrenalin junkies slacklining, zip lining, rock climbing, base jumping and gliding are employing Straightpoint wireless loadshackles, digital dynamometers and COLT clamp on line tensionmeter to measure the tension on lines and the safety of anchor points before using them - sometimes hundreds of feet in the air!

Our range of wireless loadcells are typically used with a wireless handheld display but our load monitoring data logging software and rugged Windows tablet is an increasingly popular solution in this interesting application when data and graphs need to be analysed for peak loads.

In its simplest sense, slack lining is different to tight rope walking in that the line has slack in it. When in use there is an appreciable dip in the line between the anchor points where the person is walking. Slack liners use Straightpoint loadcells to record a standing tension when the line is tightened and measure leash falls.

Product Recommendations: Clamp on line tensionmeter | Wireless Load Shackle | Software

Need a price? Contact our team

For simple logistics, shipping, ship to ship transfers (STS) weighing to measuring forces on mooring tension lines Straightpoint have a solution. Products are IP rated and constructed from marine grade materials to ensure that they remain accurate, reliable and most importantly safe for use.

For weighing up to 5t the Miniweigher plus is the go to compact crane scale for safe and accurate weighing and our best selling Radiolink plus takes care of the heavier lifts allowing the operator to safely stand at distance of 1000 metres or 3280 feet from the load.

For moving lines with no dead end to rig a digital dynamometer the TIMH dynamic load monitoring system will measure tension in motion and display either via cable or wirelessly to the monitoring station.

Need a price? Contact our team

Product Recommendations: Radiolink plus | Miniweigher plus | Running Line Dynamometer

Load monitoring products ideal for Marine Towage, Tug and Salvage

Ideal for use in bollard pull testing and monitoring line forces when towing and salvaging vessels offshore

Read our white paper, here which looks at the preventative measures you can take to improve safety.

The Radiolink plus (RLP) loadcell is constructed using aircraft-grade aluminium, making it light and durable, and finished with an anodised coating that helps it to reach the NEMA6/IP67 environmental protection by resisting corrosion. This is especially essential in order to prolong the lifespan of the product by protecting it from the wet, salty, and rough handling conditions out at sea.

Need a price? Contact our team

To even the most prepared and highly capable tug vessel seamen who are working within an offshore environment, open water conditions can suddenly become extremely hazardous to work within. During a storm, for example, a tug pulling a vessel via a metal hawser lines would be buffeted about plus these extra forces could cause the line’s operational limits to be exceeded.

If the hawser line snaps and recoils, there is a possibility that any crew caught in the “snap-back zone”, where the resulting backlash can whip back at ferocious speeds, could be badly hurt or fatally injured.

Having a tension monitoring system incorporated will provide constant real-time readouts of the forces prevailing on the line.

If the tension rises to dangerous levels then the appropriate reactions can be carried out immediately to lessen the risks.

Tug and Towage

During a tow of a vessel by a tug, if either vessel loses control (through mechanical failure or being under the influence of strong water currents), one or both could be capsized from the line being bent and pulled around the stern.

The hydraulic towing winch system is an essential piece of machinery on a tug boat and needs to kept operational. If control of the metal cable attached to the winch is lost, then substantial damage may be caused to the system from the mechanical strain inflicted upon it. The financial costs to fix it would be an unnecessary burden that could be quite easily avoided if an RLP or load pin was attached near the winch’s break stay.

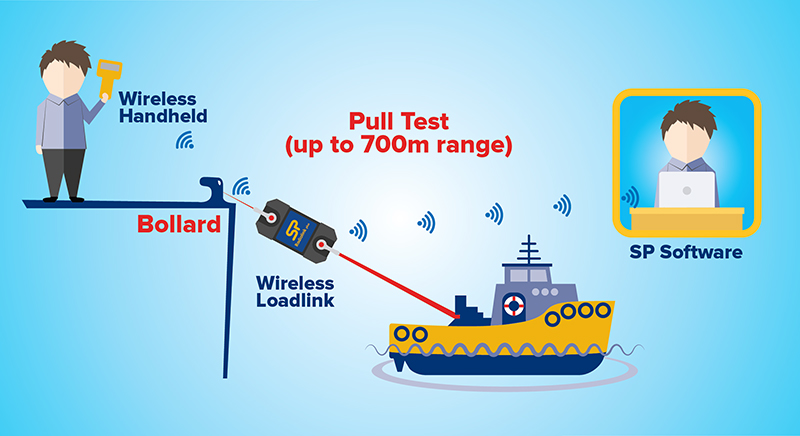

When tug boats are not pulling other vessels they can also perform bollard pull tests as a service to the port they are based at. There are two main purposes to carry out this task, firstly to test the maximum pulling capacity of the tug boat to measure its current performance, and secondly to test the bollard’s integrity. This is in order to determine if it is still able to securely moor vessels at the capacity it was originally designed to hold.

SP’s RLP load cells are ideal for use in these tests, and when linked into as part of the hawser line (beyond the bridles and pendant), it can allow the tug boat operatives to monitor the tension forces, from a safe position, via the wireless connection to SP’s Hand Held Plus display (SW-HHP).

The person in charge of the pull test will be able to remotely monitor from up to 700m/2300ft away, preventing injury from any snapped lines or bollards that break away from their foundations.

Salvage

Loadlinks can be used to save stricken wrecks that are either still afloat or have sunk below the surface of the water.

To the resulting ship/vessel casualties, which need to be recovered or salvaged, even the process of rescue is fraught with operational difficulties and hazards that have to be well managed to achieve operational success.

An experienced salvager will know that each new salvage operation is going to be different from the last. Having a dynamic monitoring system as part of the process will mean they can negate dangerous circumstances that can occur. These circumstances can include holding lines snapping, or cranes being used on the recovery vessels becoming unbalanced and toppling over. Any accident could lead to the operation becoming more difficult, lengthier, and more expensive in the long run from the original projected cost.

Crosby Straightpoint has a combination of software, instrumentation and wireless load cells (Bluetooth option and with DNV Type approval) to suit these applications.