|

|

|

|

|

|

|

|

How and where to get your load cell calibrated

Careful investment and installation of new load cell test machines enable Crosby Straightpoint and its partners to offer a world-class re-calibration and repair service.

To maintain the accuracy and function of your lifting load/force measurement products, be it Crosby Straightpoint branded or otherwise, scheduled calibration and maintenance needs to be carried out as a recommended element to owning this type of equipment to ensure continued safety and accuracy when lifting.

Authorised Calibration and Repair Service Centres

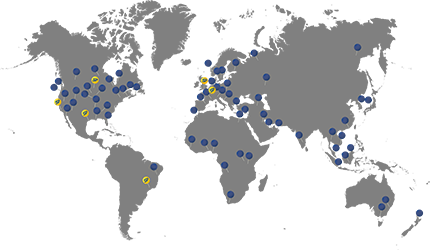

As part of Straightpoint's distinct recognition of this; we provide calibration and repair facilities based not only in the UK but worldwide, at appointed distributors spread across the globe in key locations.These locations have had intensive training to maintain Straightpoint's standards. The main advantage is having the device returned and back in action much faster than sending it to a single hub and lessening the chance of delays from worldwide transport holdups.

Straightpoint's calibration and repair industrial facilities at our UK facilities are equipped with a range of load cell calibration test rigs (with closed-loop, servo-controlled testing ability) up to 350te / 770,000lbs.

All types of load cells, dynamometers, crane scales, loadlinks and other force transducers may be calibrated and certified including Mantracourt, Strainstall, JCM Load Monitoring, Scotload, Dillon, Tractel, Eilon Engineering, Red Rooster, Elite Transducers, Yale and many more – as well as our own brand products.

Load systems used to measure and monitor forces across the industry must be optimised for peak accuracy, providing predictable output to recognised standards.

Call +44(0)2392 484491

Email our team

Industrial calibration test machines

The Straightpoint facilities can apply and exert a wide spectrum of known loads and forces - from just a few kilograms or lbs to many hundreds of tonnes – to test and calibrate load cells and force sensors supplied by clients.

Machines installed at the Straightpoint facility are UKAS ISO 17025 / NIST traceable rigs, Class 0.5 standard and certified by the National Physical Laboratory in London.

For the purposes of industrial calibration our inventory of load cell testing machines is as follows:

250kg / 550lbs dead weight

6.5te / 14,000lbs hydraulic tensile force

6.5te / 14,000lbs hydraulic compressive force

12te / 25,000lbs hydraulic tensile force

2 x 50te / 110,000lbs hydraulic tensile force

50te / 110,000lbs hydraulic compression force

100te / 220,000lbs hydraulic tension and compression

350te / 770,000lbs hydraulic tension and compression

When to calibrate load cells, digital dynamometers and other force sensors?

Load cells tend to become unstable or drift for a variety of reasons.

Factors that can adversely affect function include the gradual degrading of the load cell, instrumentation fault development, cabling and termination, electrical influence and mechanical effects.

Failure to inspect or clean load cells is a significant factor that can lead to operational, functional and calibration issues.

Particulate matter can build up around load cells and load cell mounts over time, even in clean environments.

Outdoor load systems face more variable-to-extreme conditions. Weigh systems such as crane scales are subject to inclement and seasonal changeable weather, leading to problems developing in previously accurate load cells. A typical problem might be with connected load cell drains that can cause force sensor failure over time.

Calibration technicians in our service department are always available to discuss client requirements and related load cell and force measurement issues.

Important Warning: When a load system fails to function, not delivering any force measurement or monitoring information, do not simply disconnect the system.

An investigation of the full load system is normally required to ensure the return to safe and high-performance operation. Simple re-calibration of a single faulty load cell within a system may have dangerous effects leading to mechanical failure.

Certified load cell calibration service

Straightpoint and our partners offer world-class aftersales, care and calibration and are committed to a FAST turn round, endeavouring to calibrate, certify and despatch equipment to any international location worldwide.

Calibration technicians in our service department are always available to discuss client requirements and related load cell and force measurement issues.