Load monitoring systems are ideal for wind turbine construction projects.

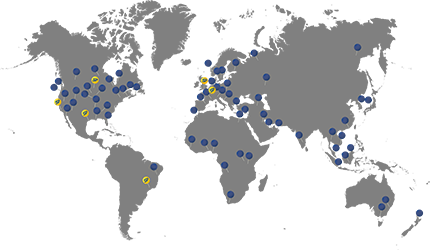

SP products have been put through rigorous testing regimes and meet the high standards of many globally recognised industry bodies such as ASME, DNV-GL type approval, with a range of intrinsically safe wireless products. They have also developed them to be used with a wide range of industry standard lifting shackles and equipment.

Today, windfarms have now become a great renewable energy option to producing electricity with the benefits of zero carbon emissions and high energy outputs. SP supports the drive to produce energy in an environmentally friendly way with the same passion as it puts into producing innovative and industry leading load monitoring products. Providing the tools to improve safety levels that lead to a successful development completion with no injuries and loss of life occurring.

In turn, when projects are not hindered by disruption, investors can see operational costs tumble down and profitability rising.

Making the wind turbine construction and management industry a safer place

The lifting and rigging industry, as well as the specialists working within it, have been integral to helping the wind power industry to expand and flourish.

To keep up with this rising demand in wind farms the number of people and equipment involved has also jumped up to match the expansion’s pace.

SP products can be best utilised:

- Calculate Centre of Gravity of a monopile or offshore jacket

- Loler Test the hoist tower

- High capacity cranes for lifting the main components such as the nacelle, blades, tower sections, etc.

- Lorry mounted loader cranes transporting the parts to site

- Manual chain hoists for scenarios where heavy lifting equipment cannot be used

We can supply load monitoring solutions for each of them, such is the diversity of our solutions on offer to cover many parts to the construction process.

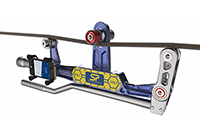

The range of wireless load cells are ideal for measuring the load for transportation.

Also utilised by LOLER inspection specialist to test the hoist in the tower before any actual payload lifting takes place.

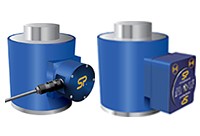

SP compression load cells with wireless centre of gravity (WCOGS) software can be used to weigh and correctly calculate COG of the monopile or offshore jackets that support the turbine.

Using the latest in IEEE 802.15.4 (2.4GHz) technology; monitor the lift in safety from up to 700m/2300ft away, with its high integrity, error free transmission, wireless connectivity capability.

With accessories on offer you will be able to set overload and underload alarms so that you are instantly aware when the lifting equipment is exceeding its safety limits.

Both sea currents and weather play out as major factors that fight against the process to establish the wind turbine’s platform/base. So having accurate load force data to monitor before and during the lift is essential.

Offshore Locations & Marine Construction

Working in marine conditions brings a myriad of extra challenges to complicate and add additional hazards to the entire process. Firstly, a much more work has to go into securing the base of the turbine to a stable foundation. This usually involves 1 of 5 jacket types to fix the tower into place:

- Monopile

- Gravity-based

- Tripod

- Jacket

- Tripile

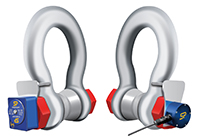

Straightpoint have a combination of software, instrumentation and wireless load cells (bluetooth option and with DNV Type approval) to suit these applications.

Product Recommendations:

Radiolink plus | Wireless Load shackle | Compression loadcells | Software wireless centre of gravity

Event Staging and Rigging Industry

Concerts, theatres, circuses and many other entertainment venues across the world are using Crsoby Straightpoint load cells coupled with our impressive range of displays and load monitoring software to watch and maintain loads or dynamic forces on lighting, scenery and video screen rigging applications.

Our wireless technology sets the Straightpoint range of load cells apart in this industry where multiple load cells and fly points are common. Cable free solutions with high speed PC software allows instant feedback to stage rigging supervisors.

Need a price? Contact our team

Product Recommendations:

Wireless Load Shackle | INSIGHT

Water Bag Testing

Crane testing with water bags or other weights or fixed load points is an ideal application for the Straightpoint range of load cells. Our Radiolink plus or Wireless shackle load cells used in parallel with our wireless data logging packages testing can be performed at a safe distance and all dynamic and static forces logged for later analysis and client approval.

What equipment is tested?

At the most basic level this could be any equipment or structure that lifts, holds, supports or resists a load. Typically the item will have a rated WLL, as mentioned previously.

Here are some non-exhaustive examples:

- Bollard pull tests

- Tug tests

- Crane tests (using water bags, block weights)

- Pad eye or fly point tests

- Crash barrier tests

- Lifting equipment tests (slings, chains, wire rope, hooks)

- Construction equipment tests (shoring columns, Acrow props, lintels)

- Lifting and spreader beam tests

- Hydraulic cylinder load tests

Some of those items will be proof tested in tension, for example, slings, chains, wire rope and cranes, while others will be tested in compression, for example, Acrow props, spreader beams and hydraulic cylinders.

Need a price? Contact our team

Straightpoint have a combination of software, instrumentation and wireless load cells (bluetooth option and with DNV Type approval) to suit these applications.