The nature of an Arborist’s line of work is lined with a high number of risks. Where if anything goes wrong it can lead to damaged equipment and assets, injury, or even fatalities.

When you work at height you want to be assured the rigging lines will be able to take the weights and forces inflicted upon them. Because if a line’s tolerance is exceeded (leading to it failing and snapping), then it can instigate a catastrophic series of events. Beyond the initial accidental damage - further harm can be inflicted upon business reputation.

Every tree and its location is unique, so when one needs maintaining or felling, it needs to be thoroughly assessed before being tackled.

A tree’s location near to property or other types of valuable hard to move assets can throw up extra challenges. It may mean that it cannot be felled as a whole because of the risk of it damaging these structures or assets.

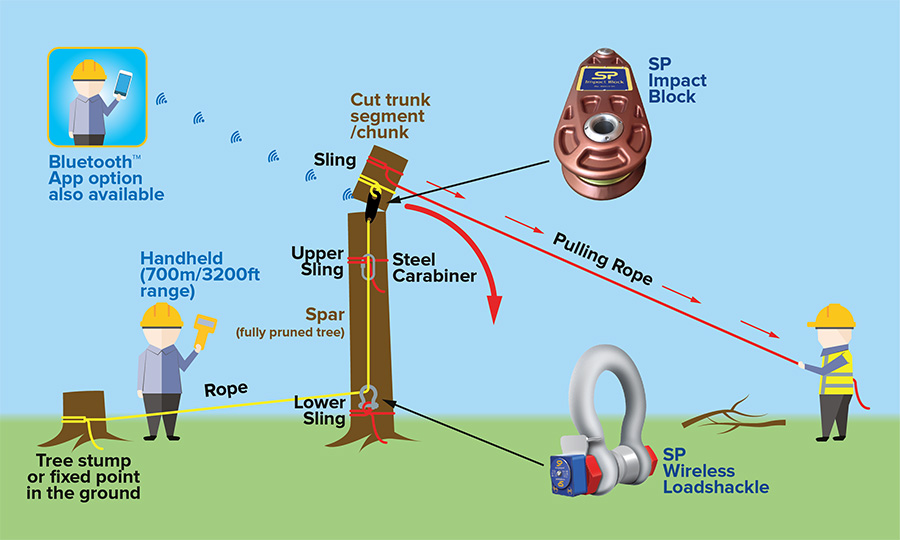

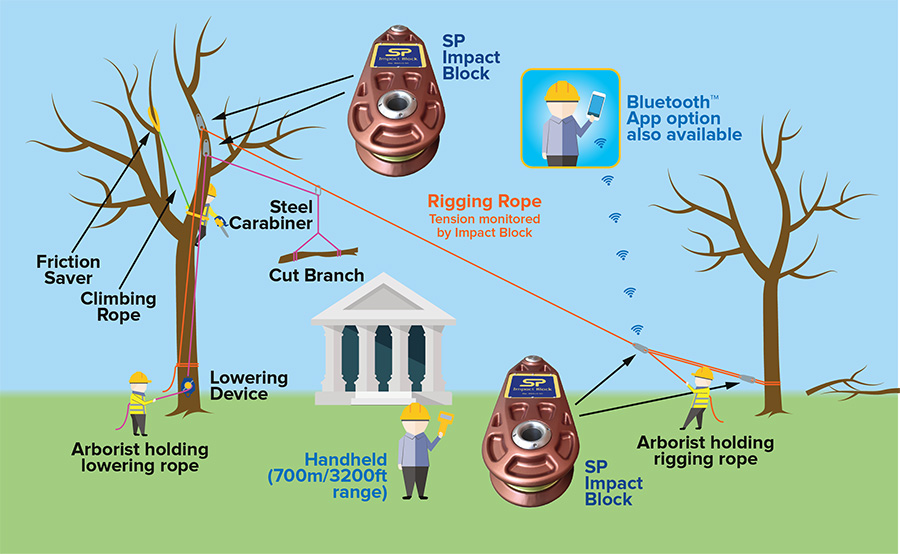

The alternative method is to take it down branch by branch, trunk segment by segment. Our loadcells are ideal to be utilised within this situation in order to maximise safety and providing a higher guarantee of successfully completing the job.

We understand the dangers and provide rugged and reliable product solutions so our load monitoring products provide the following relevant features:

- Bluetooth connectivity – monitor line loads using our free HHP app (iOS & Android) from up to 100m (328feet) safe distance away

- Monitor to up to 700m (2400feet) away using our HHP hand held device with radio telemetry

- IP67/NEMA6 environmental protection – protected from any outdoor heavy weather conditions involving wind and rain

- Rugged hard wearing design that can be used in a variety of heavy use applications out in the field.

- 2 Year Warranty

- Massive battery life of 1200 hours operational time

Need a price? Contact our team

IMPACT BLOCK

IMPACT BLOCK

The safest choice for the working Arborist. Manufactured in partnership with DMM (dmmclimbing.com), the Impact Block has been designed to deliver the best performance in terms of alignment, resistance and appeal. The aesthetic curves of the Impact Block combines beauty, strength and durability to ensure a rope friendly surface. It is designed to be used as a dynamic tension measuring tool that can replace a general rigging pully block. Lightweight attachment sling facilitates hauling of block, sling and rope to the climber and helps with handling, in tree stowage and workshop storage.

Features

- Rounded edges to cheek plates maintain low rope abrasion when rope is fed ‘unfair’

- Upper sheave opens via a threaded locking axle for added security

- Thrust surfaces increase tolerance to external loading of spindle and anchor pin

- Direct connection to cordage, the anchor slings helps ensure correct neighbour component compatibility

Ideal for use with the following applications:

Ideal for use with the following applications:

- Arborist

- Tree Felling

- Tree removal

- Tree trimming

- Tree pruning

Product Recommendations:

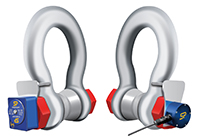

Radiolink plus Load Cell | Impact Block | Wireless Load Shackle

Download our Arborist/Tree Felling brochure for information on how our products can help you stay safe.

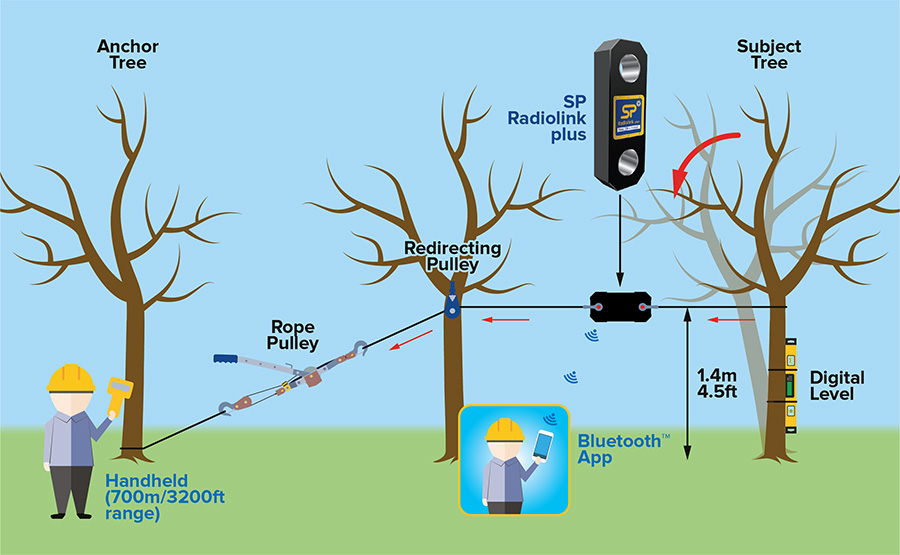

Tree stability testing

TREE STABILITY TESTING

This diagram is showing how an arborist can test the stability of a tree using an SP Radiolink Plus loadcell to measure the trunk’s resistance. As the line is pulled tighter using the pulley the loadcell will allow the arborist to monitor/measure the force applied to the subject tree. This is to prevent the tree from falling over if resistance is found to be low. The tree’s stability depends on the condition of the soil the tree sits in.

The tension in the diagonal guy-wire, combined with the compression and buckling strength of the structure, allows the structure to withstand lateral loads such as wind or the weight of cantilevered structures.

Wire ropes are complex; composition, size, construction, type of core and lay all need to be considered. A 1x7 rope behaves differently to a 7x19 or 6x36 rope; even wire ropes of the same diameter will calibrate differently because of varying rigidity.

So, when the guy wires retaining communication towers & flare stacks, pre-tensioned cable barriers, elevator cable maintenance, overhead electric transit wires, catenaries, fall arrest systems or utility cables need fast and accurate measurement of tension and line sage in situ then look no further than the Straightpoint Clamp on Line Tensionmeter or COLT. COLT Brochure

Supplied with a Bluetooth smart phone (Android or Apple iOS) load monitoring app that contains an infinite wire rope library the COLT measures tension on wire rope up to 11,000 lbf / 5,000 kgf and up to 1 inch / 25mm diameter.

Fully adjustable, it clamps onto pre-tensioned wire ropes, eliminating the need for additional sheaves or tooling, as is the case with alternative solutions available on the market.

Product Recommendations: Clamp on line tensionmeter

Need a price? Contact our teamCrosby|Straightpoint stock up to 500te Tension and Compression Load Cells as well as Loadshackles. SP can also produce cells for projects up to and over 2000te

From stock Crosby|SP supply up to 500te Tension and Compression Load Cells, and with a vertically integrated supply chain they can also supply larger capacities and custom orders.

When abnormal loads are in the upper ranges of what can lifted (in both overall weight and distribution of weight), close to the capacity of human ingenuity and technological capabilities; load monitoring cells are often used to help ensure the safety of the move.

This can also include cargo that is ‘Out-Of-Gauge’ (O.O.G), i.e. objects that do not fit within the constraints of a normal freight container, and also ‘Breakbulk’ that may have inconsistent load distribution from irregular internal configuration.

During the lifts, two types of wireless load cells are recommended to be used:

- Compression load cells

- Tension load cells

In situations like large steelworks, a wide variety of heavy and tandem lifting projects are carried out. These kinds of projects would include bespoke/unique castings with uneven weight distribution and come in huge units of weight. Compression cells, which can be wirelessly connected and used in conjunction with an ISO19901 compliant centre of gravity INSIGHT software package, will monitor the load at different points over the cast. This will allow the person managing the lift to discover where the heaviest sections are and adjust where the lifting points are.

At the same time, a Radiolink plus load cell(s) can be used as a ‘below-the-hook’ solution to monitor the weight as it is lifted. The load cell can also measure the load at different points to see where the centre of balance is.

Need a price? Contact our team

Experienced engineers/consultants that specialise in heavy lifts, who are employed by specialised freight forwarders, have huge responsibilities to achieve a successful and safe delivery with every project. Our load monitoring products our engineered to the highest standards, ensuring high reliability and accuracy, which are essential requirements for the co-ordinators managing these projects.

Examples of abnormal loads:

- Large steel works

- Heavy plant machinery

- Turbines

- Generators

- Distillation columns

- Modular accommodation – COG is not known due to different configurations inside

Product & Software Recommendations:

Radiolink plus Load Cell | Wireless Compression Loadcell

Wireless Centre of Gravity System | Multi Operations Survey System

Safety of Life at Sea (SOLAS)

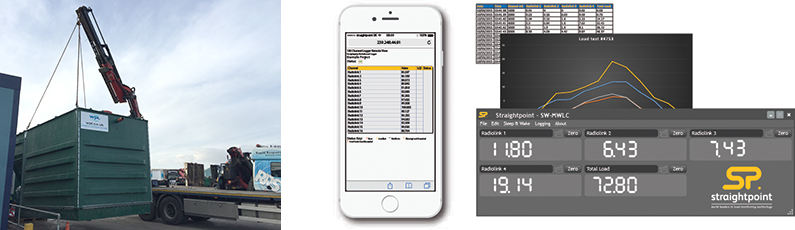

This is a new requirement where shippers are now legally required to declare the weight of shipping containers before they are booked onto a ship. The idea is to avoid the situations, shown left, which occur when a container ship is overloaded.

This is a new requirement where shippers are now legally required to declare the weight of shipping containers before they are booked onto a ship. The idea is to avoid the situations, shown left, which occur when a container ship is overloaded.

The legislation is about ‘safety of life at sea’ and aims to prevent overloading and uneven loading of ships to prevent accidents.

The new SOLAS requirements have meant shippers, packers and intermodal logistics companies are looking for simple ways to integrate container weight information into their current processes. You can read more about SOLAS container weighing regulations here.

At Straightpoint we believe the simplest and fastest way to capture this weight information is when the container is lifted.

This can be done using a loadlink or loadshackle used in conjunction with our datalogging software for reporting.

Product Recommendations:

Radiolink plus Load Cell | Wireless Load Shackle | SW-MWLC datalogging software

Need a price? Contact our team