News & Case Studies

- Details

- Written by Administrator

Load Cell Measures Dredging Line Tension

A 2.5-ton capacity SP Radiolink plus load cell measures tension on a line stretching across a lagoon, upon which a dredge travels at a biosolids management facility, part of the City of Eugene Waste Water Dept., in Oregon, U.S. The RLP was added to inventory at the start of the latest six-month biosolids management season in March, where it replaced a dynamometer that was not suited to working in the elements.

The load cell is connected to a land-based lateral move system that allows the dredge to move from side to side as well as forwards and backwards to harvest biosolids in the lagoon. Biosolids management relates to treated sewage sludge that is intended to be used as soil amendment.

The Radiolink plus boasts a separate internal sealed enclosure providing the load cell's electronic components with IP67 environmental protection even with the battery cover plate missing, making the dynamometer suitable for use in the harshest environments. Measurements are taken on a wireless Hand Held Plus in the cab of the dredge.

Due to the nature of the environment and exposure to corrosive hydrogen sulfide (H2S), SP took extra precautions to protect the delicate strain gauges and electronics by coating the internal components of the load cell with a special epoxy resin resistant to H2S. Contrail Smith, a lead at the biosolids management facility at City of Eugene Waste Water Dept., said, “The dynamometer we were using previously was hard-wired and wasn’t suited to working in the elements.

The RLP gives us both the luxury of wireless information and durability in outdoor application. It’s performed well this season and we’re pleased we found the product during online research during our off-season.” He added, “We monitor the tension on the line as a safety measure; we like to keep the tension around 2,000 lbs. of tension, so the operator keeps an eye on the Hand Held Plus whilst dredging. During the season, the dredge is operational every day for six months—that’s over 180 days—so we need to work with equipment that is reliable; the RLP fits that requirement.” Smith explained that the City of Eugene Waste Water Dept. is likely to be among the first of its kind to apply a load cell to such dredging applications. He said, “We are often visited by our peers from other sites and find that they apply our methods and technologies to their own facilities. I don’t know how many, if any, other sites are using load cells but it’s not likely to be commonplace.”

The lagoons (or ponds) at the facility measure 675 ft. long by 275 ft. wide.

- Details

- Written by Administrator

SP Load Cells Provide Data for Ship-to-Shore Crane Project

Lifting Gear Hire (LGH) provided 16 wireless compression load cells from Straightpoint to perform benchmark weighing as 10 ship-to-shore cranes were raised 10m by Shanghai Zhenhua Port Machinery Company (ZPMC) at Port of Los Angeles.

The 150-metric tonne capacity load cells combined to weigh one Noell ship-to-shore container handling crane, originally estimated to have a weight of 1,350te, and provide benchmark data before it and nine other cranes were to be raised by APM Terminals to accommodate larger ships calling at Pier 400 of the port.

The project, managed by ZPMC North America, involved raising the cranes slightly more than 10m and inserting longer leg sections; it was a collaborative effort between the crane’s original equipment manufacturer (OEM) and ZPMC. Structural fabrication of the new leg sections and frame bracing was accomplished at ZPMC’s Shanghai facility.

Rick Pope, vice president at ZPMC North America, explained that a key part of the project included benchmark weighing of one raised crane to determine the new, as-built weight and center of gravity. He said: “From this data, the crane OEM calculated the required concrete ballast that needed to be added to establish the crane’s designed operational center of gravity and stability. The results became the basis of ballasting for the other cranes being raised.”

The weighing procedure included lifting the crane utilizing ZPMC’s self-propelled modular trailers, placing the load cells in pairs under the eight intermediate gantry equalizers on specially designed pedestals, and lowering the crane down to rest on the load cells. The crane was lifted off the load cells between trials to allow for three distinct weighing evolutions.

The initial as-built weight of the crane as provided in historical documents was 1,185te. Post-construction weighing indicated the raising added 193te, for a total pre-ballast weight of 1,378te. Concrete ballast was added according to OEM specifications and resulted in a post-ballast weight of 1,414te and shift of the operational center of gravity approximately 1m toward the rear of the crane.

LGH also provided a rugged SP wireless tablet with data logging software and USB wireless base station. The data logging software provided user-configurable screens, recording the physical location of the load cells and collection of data. Center of gravity software collected data over three trials of weighing to calculate an average. A report was automatically created upon completion of the tests, including each load cell’s load, location, calculated center of gravity and standard deviation of weight data.

John Molidor, director of projects and market development at Straightpoint, said: “It was great to witness the application in person and get a first-hand impression of the 16 load cell system delivering safety and accuracy to such a landmark project. We enjoyed working with LGH and ZPMC North America to deliver the state-of-the-art solution.”

- Details

- Written by Administrator

Loadshackle Monitors Sewer Pump Station Cylinder Removal

Dynamic Rigging Hire (DRH) supplied a 25t Wireless Loadshackle from Straightpoint and other rigging gear for removal of a large hydraulic cylinder at a Melbourne Water sewer pump station in Australia recently.

Melbourne Water supplies drinking and recycled water, whilst managing the city’s water supply catchments, sewage treatment, rivers, creeks and major drainage systems. It is conducting an ongoing maintenance programme at one of its major pump stations in the western suburbs. Integral to the project was removal of the cylinder for overhaul at an offsite machine workshop.

DRH provided the engineering contractor with all the required rigging equipment needed to lift and rotate the cylinder out of position. Utilising an SP Wireless Loadshackle and Hand Held Plus, it monitored the weight of the cylinder as it was lifted from the floor of a deep shaft in the centre of the pump station.

The cylinder weighed approx. 23t, while another two, weighing 13t, will be removed at a later date. Ross Johnson, general manager at DRH, explained that the cylinders are similar to smaller, hydraulic units that one might see under a tip truck or earth moving machine—just much bigger, he said. They open and close the gate (like a valve) in the sewer system.

The cylinder weighed approx. 23t, while another two, weighing 13t, will be removed at a later date. Ross Johnson, general manager at DRH, explained that the cylinders are similar to smaller, hydraulic units that one might see under a tip truck or earth moving machine—just much bigger, he said. They open and close the gate (like a valve) in the sewer system.

The contractor utilised a 55t capacity overhead crane that spans the building in addition to a 25t capacity mobile crane; each crane was connected to the load at two pick points. The overhead crane was rigged with grade 100 (grade 10 in UK) chain slings that connected at either side of one end of the cylinder frame as it was lifted vertically. The mobile crane, meanwhile, rigged with the same type of chain and longer, synthetic slings, lifted from the bottom as it was raised beyond the level of the shaft entrance.

DRH supplied a set of Gunnebo grade 100 alloy steel master links for the main hook of the overhead crane, rigged into a 55t shackle and then the 25t load shackle with the two-leg chain sling.

Johnson said: “We were chosen as a specialist supplier of the below-the-hook equipment, including a force measurement solution that could confirm the weight of the load so we wouldn’t exceed the capacity of the rigging gear, cranes and / or transportation. The Wireless Loadshackle was therefore intrinsic to the custom package we assembled for the engineering contractor responsible for safe and efficient completion of the lift.”

The Wireless Loadshackle is particularly suited to low headroom applications. Additional features include its hard anodised aluminium electronics enclosure and an internal chassis providing IP67 / NEMA6 environmental protection even with the battery cover plate missing.

DRH provides a comprehensive range of rigging, hoisting and load measurement equipment across Australia from Melbourne headquarters. It frequently facilitates provision of a wide range of kit to a diverse client base including crane, construction, engineering, manufacturing, offshore and service projects.

- Details

- Written by Tanya

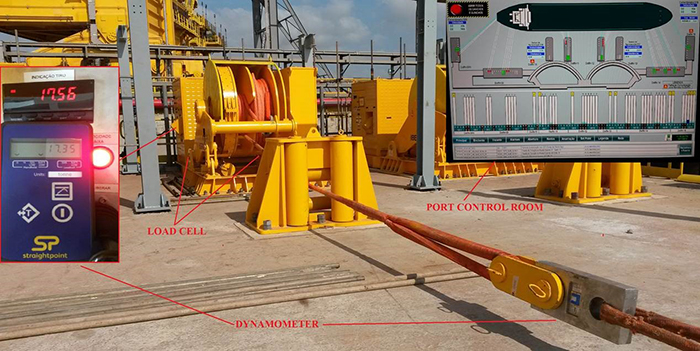

Straightpoint Load Cells Test Mooring Equipment at Huge Port Project

Straightpoint force measurement technology has been used to test mooring equipment at Pier IV of the monumental Ponta da Madeira Maritime Terminal (TMPM), in Maranhão, Brazil. The port is part of the S11D mining project that has been designed to accommodate Valemax ships, a fleet of large ore carriers that carry up to 400,000 metric tons and are 362m long by 65m wide.

Vigo, Spain-based Ibercisa Deck Machinery was contracted by the S11D project, located in São Luís on Brazil’s northern coastline, to install 26 identical 100t capacity mooring winches and 50 150t capacity fairleads, for the new pier that will be the point of departure for vessels from the Carajás mine, bound for Asia, Oceania and Europe.

Ibercisa utilised 52 custom loadpins (two for each winch) with 4-20mA analogue outputs for PLC integration, designed for use in applications where an end of line load cell cannot be used and an integrated solution is required; and a 150t capacity Radiolink plus, commonly applied in marine, offshore, oil and gas applications.

All winches were calibrated at the factory and again at the port, while the Radiolink plus was utilised to calibrate the loadpins when mounted onto the winches and then to test the machines. The fairleads are essentially rings that guide ropes, keeping them clear of obstructions and preventing them from cutting or chafing.

Manuel Ricardo Romero Vega, project manager at Ibercisa, said: “Because of the strong tidal currents and lack of a breakwater, the pier has land-based cables that help to moor ships to the berths. Given the importance therefore of the winches and fairleads, TMPM represents a landmark project for Ibercisa.”

David Ayling, director at Straightpoint, said: “This project will be memorable for a number of reasons. The first point of contact was at a trade show where we were exhibiting with our distributor, Rigmarine. It was rewarding to enter dialogue with Ibercisa face-to-face and explore force measurement solutions for their challenging scope of work at TMPM.”

He added: “Delivery of the loadpins and Radiolink plus marked completion of our first order from them and we hope it represents the start of a long-term relationship. We relished the challenge of custom manufacturing 52 loadpins, which are essentially round shearpin load cells enabling load measurement in mechanical joints, to the specifications of the winches Ibercisa was to install at the port.”

Vega said: “Straightpoint manufactured an excellent custom solution and, following initial discussions, we were confident they would suit our requirements for this demanding project. The loadpins and dynamometer [Radiolink plus] performed under pressure and the manufacturer was able to deliver the custom units to site to a short lead time.”

The expansion of TMPM is the final stage of the logistics phase of the S11D project and incorporates both onshore and offshore expansion. The centrepiece of the offshore development is Pier IV, also called the northern berth, equipped with a ship loader that replicates the southern berth’s existing design.

- Details

- Written by Tanya

Straightpoint has named a distributor in Russia, as Euro-Lift, based in Tolyatti near Samara on the Volga River, joins the company’s expanding dealer network.

Straightpoint has named a distributor in Russia, as Euro-Lift, based in Tolyatti near Samara on the Volga River, joins the company’s expanding dealer network.Integral to Hampshire, UK-headquartered Straightpoint’s growth strategy is partnerships with lifting-centric businesses across the world. A commonality of these distributors is their portfolios of equipment from leading manufacturers of hoists, rigging gear and below-the-hook components.

Euro-Lift will add Straightpoint’s range of force measurement, load monitoring and suspended weighing load cell equipment to its range of quality lifting and rigging hardware that includes shackles, chain, wire rope, clamps and other related equipment, which it supplies to oil and gas, power generation, machinery, metallurgy and construction professionals from its base in the south west of the country.

David Mullard, business development manager at Straightpoint, who recently returned from Tolyatti, said: “Euro-Lift represents a great fit with SP; they are an organised and dynamic team with a clear, long-term growth strategy. The company is committed to quality products and trusted brands. Importantly, they are also an established company with a core focus on lifting safety.”

Top of the agenda during the recent visit was training as Euro-Lift took delivery of a small stock of demonstration products to introduce the technology to customers. Mullard alluded to the importance of giving new distributors and, in turn, end users the ability to get a sense of quality through hands-on interaction with equipment.

He said: “Euro-Lift’s general manager [Garik Mardoyan] understands the market, the customers and the competitive landscape. The team knows who to reach, how to engage in dialogue with them, and can support that activity with tailored literature in the local language. A local partner like this provides elevated service levels in tune with market trends that satisfies customers and grows a business—that approach is intrinsic to Straightpoint stratagem.”

Mullard added: “True to their name, Euro-Lift is a Russian business with a strong European focus and an international outlook. The company has invested in the best IT systems to underpin quality manufacture and order fulfilment. From quotation to receipt of PO, factory floor manufacture and dispatch, everything is traceable and well organised.”

He anticipates that Straightpoint’s most popular product, the Radiolink plus load cell, will be well received by Russian industries, but added that there is “great potential” for the wireless compression load cells for centre of gravity calculation of heavy loads, and the new digital product for measuring tension on static lines—the Clamp On Line Tensiometer (or COLT).

In conclusion, Mullard said: “In the medium term and once we have spent time developing and promoting SP in the region, I believe Euro-Lift will be in a strong position to stock product locally, available immediately. They have also expressed an interest in calibration and service of Straightpoint products, which is an ambition that we support as we look to ensure they reach their full potential.”