Loadshackle Monitors Sewer Pump Station Cylinder Removal

Dynamic Rigging Hire (DRH) supplied a 25t Wireless Loadshackle from Straightpoint and other rigging gear for removal of a large hydraulic cylinder at a Melbourne Water sewer pump station in Australia recently.

Melbourne Water supplies drinking and recycled water, whilst managing the city’s water supply catchments, sewage treatment, rivers, creeks and major drainage systems. It is conducting an ongoing maintenance programme at one of its major pump stations in the western suburbs. Integral to the project was removal of the cylinder for overhaul at an offsite machine workshop.

DRH provided the engineering contractor with all the required rigging equipment needed to lift and rotate the cylinder out of position. Utilising an SP Wireless Loadshackle and Hand Held Plus, it monitored the weight of the cylinder as it was lifted from the floor of a deep shaft in the centre of the pump station.

The cylinder weighed approx. 23t, while another two, weighing 13t, will be removed at a later date. Ross Johnson, general manager at DRH, explained that the cylinders are similar to smaller, hydraulic units that one might see under a tip truck or earth moving machine—just much bigger, he said. They open and close the gate (like a valve) in the sewer system.

The cylinder weighed approx. 23t, while another two, weighing 13t, will be removed at a later date. Ross Johnson, general manager at DRH, explained that the cylinders are similar to smaller, hydraulic units that one might see under a tip truck or earth moving machine—just much bigger, he said. They open and close the gate (like a valve) in the sewer system.

The contractor utilised a 55t capacity overhead crane that spans the building in addition to a 25t capacity mobile crane; each crane was connected to the load at two pick points. The overhead crane was rigged with grade 100 (grade 10 in UK) chain slings that connected at either side of one end of the cylinder frame as it was lifted vertically. The mobile crane, meanwhile, rigged with the same type of chain and longer, synthetic slings, lifted from the bottom as it was raised beyond the level of the shaft entrance.

DRH supplied a set of Gunnebo grade 100 alloy steel master links for the main hook of the overhead crane, rigged into a 55t shackle and then the 25t load shackle with the two-leg chain sling.

Johnson said: “We were chosen as a specialist supplier of the below-the-hook equipment, including a force measurement solution that could confirm the weight of the load so we wouldn’t exceed the capacity of the rigging gear, cranes and / or transportation. The Wireless Loadshackle was therefore intrinsic to the custom package we assembled for the engineering contractor responsible for safe and efficient completion of the lift.”

The Wireless Loadshackle is particularly suited to low headroom applications. Additional features include its hard anodised aluminium electronics enclosure and an internal chassis providing IP67 / NEMA6 environmental protection even with the battery cover plate missing.

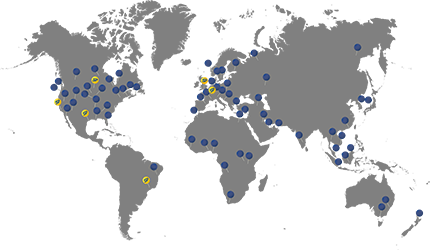

DRH provides a comprehensive range of rigging, hoisting and load measurement equipment across Australia from Melbourne headquarters. It frequently facilitates provision of a wide range of kit to a diverse client base including crane, construction, engineering, manufacturing, offshore and service projects.