News & Case Studies

- Details

- Written by Tanya

Straightpoint launches centre of gravity finder

Straightpoint launches centre of gravity finder

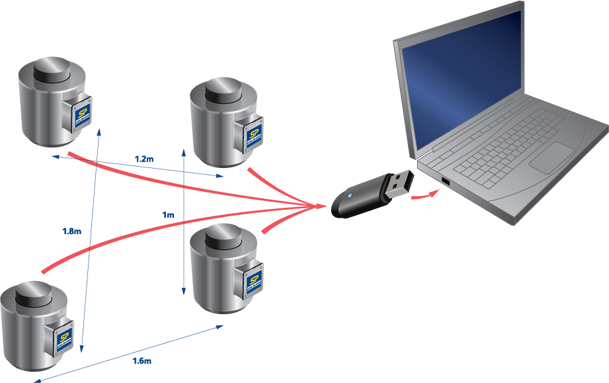

UK-based Straightpoint (UK) Ltd., a manufacturer of force measurement, load monitoring and suspended weighing load cells, has launched what it claimed to be the first off-the-shelf wireless centre of gravity system of its type in the world.

UK-based Straightpoint (UK) Ltd., a manufacturer of force measurement, load monitoring and suspended weighing load cells, has launched what it claimed to be the first off-the-shelf wireless centre of gravity system of its type in the world.

The technology is ideal for helping to ascertain the weight and centre of gravity of large structures or items with an uneven weight distribution. It produces a centre of gravity report through readings taken via the wireless dongle and PC software, which is connected to up to eight wireless compressive load cells.

As the tool is wireless, it is quicker and safer than a cable-led system and it can be used on items up to 4,000 tonnes in weight. It can ensure the safe lifting and unloading of items that do not have an evenly distributed weight, particularly useful in the offshore market.

- Details

- Written by Tanya

Straightpoint Load cell Destruction Test - Video

This is a test to destruction of a straightpoint 35te load cell. Watch as over 177te is applied until load cell finally yields to this massive force.

- Details

- Written by Tanya

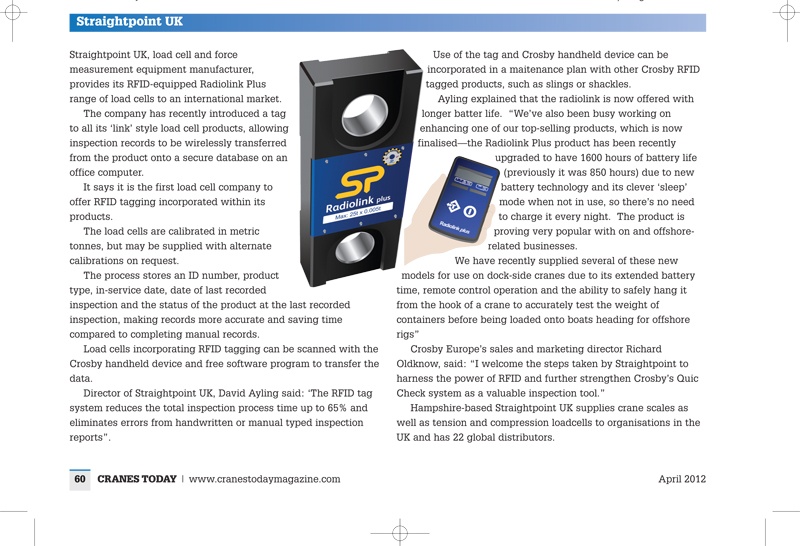

Straightpoint UK, load cell and force measurement equipment manufacturer

Provides its RFID-equipped Radiolink Plus range of load cells to an international market.

- Details

- Written by Tanya

BBC film radiolink load cell system

Measuring Airbus 380 wing forces.

{youtube}LFnwp__lDs4{/youtube}

A cutting edge 'state of the art' wireless load monitoring system manufactured and supplied by Straightpoint is being used in a £10bn programme to keep the world's largest airliner, the Airbus 380, in the skies.

The international UK-based company was contracted to supply a radio load link system to ensure the complex 29-tonne wings of the majestic aircraft - which act as fuel tanks - are perfectly balanced in flight.

Straightpoint Managing Director Dave Ayling's load systems expertise was called upon to deliver and install one of the firm's high accuracy force measurement load cell systems to enable Airbus 380 engineers to check wings for safety and reliability as they are produced at the UK's biggest factory at Filton, near Bristol.

Straightpoint is currently being featured on BBC television's iPlayer after their work was filmed in the corporations's 'How To Build...' documentary series, this one entitled 'How to Build a Super Jumbo Wing'.

MD Dave Ayling said: "The BBC documentary brings to life the amazing technology in our very modest looking load cell products. The remote sensors assist engineers to check the centre of gravity is correct in the Airbus wings.

"It is immensely satisfying to see that the awe-inspring Airbus 380, an aviation marvel, is able to take off, fly and land due to the engineering expertise in our little black boxes."

- Details

- Written by Tanya

Loadcell hire division now launched

Due to demand, we recently launched a load cell hire division for loadcell force sensors ranging from 500kg to 250tonnes, available immediately on a weekly or longer term basis.

Prices start from just £80 per week and the range includes both compression and tension loadcells, all pre-calibrated and supplied with certificates and, as standard, our 12 month Straightpoint warranty.