Straightpoint unveils massive calibration machine

Straightpoint unveils massive calibration machine

21 September 2010

Straightpoint officially launched its 350-tonne test, repair and calibration facility in a ceremony at its premises in Havant, UK. The company claims the machine, which tests and calibrates load cell force sensors, is the only one of its type in Europe.

The Deputy Mayor & Deputy Mayoress of Havant joined David Ayling, MD of Straightpoint to cut the ribbon and launch the machine. It allows the testing and calibration of load cells with up to 350 tonnes of compression and 350 tonnes of tension.

The Deputy Mayor & Deputy Mayoress of Havant joined David Ayling, MD of Straightpoint to cut the ribbon and launch the machine. It allows the testing and calibration of load cells with up to 350 tonnes of compression and 350 tonnes of tension.

Straightpoint will use the new machine to test and calibrate its own products before global shipping, as well as to regularly test and calibrate companies’ own load cell equipment. At the open day, Ayling carried out demonstrations of the equipment, including the new machine, testing the tension of a 250 tonne load cell, which has been ordered by a lifting company in France.

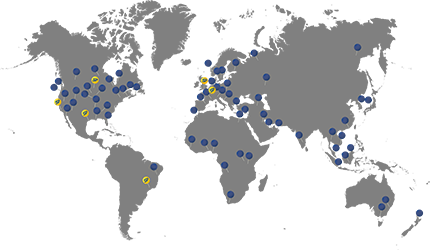

Ayling said: “We made quite a few bespoke alterations to the premises in order to house our new machine, as it weighs in at 17 tonnes and is 6 meters high. We also have the space to handle increased capacity, as we see demand for our services increase globally through our 25 distributors.”

He added: “Just to put the power of this machine into perspective, our new testing machine would easily be able to lift either the main A frame of the London Eye or up to 235 family cars, as either are within the maximum 350 tonnes capacity of our testing and calibrating machine.

“The new machine includes a hydraulic power pack and incorporates ‘reference load cells’, which The National Physical Laboratory calibrated against a master load cell, and stores in London so that the load is always traceable and accurate. The new machine can hold the load extremely steadily, which is important should we need to make adjustments to the load cells being tested. We proof test load cells up to double the safe working load, which we carry out three times to ensure the loadcells are mechanically safe.

“To finish the test procedure, we would then calibrate with the relevant set of electronics, such as a wireless or integral display; the load cell is ready to ship off to the customer quickly. Without testing a load cell, the consequences could be catastrophic – for example, a crane lifting a container heavier than its maximum load that hasn’t been tested using a properly calibrated load cell would be disastrous, potentially causing crane collapse and untold damage to operators of the machine as well as the machinery and container contents. Just by using a properly calibrated and tested load cell, the operator would be able to accurately gauge the maximum weight and carry out the lifting safely.”