New Load Cell Test Facility at Straightpoint HQ

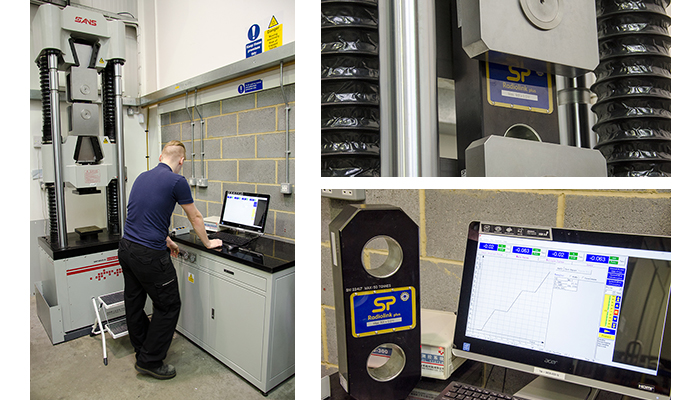

A state-of-the-art 100t universal test machine is the centrepiece of a new load cell testing facility at UK manufacturer Straightpoint’s headquarters in Hampshire.

The machine, manufactured by USA company MTS, can test in compression and tension, offering the ability to test Straightpoint’s entire range of load cells up to 100t.

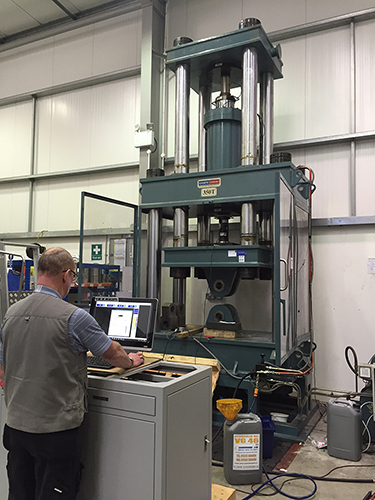

Meanwhile, as part of ongoing investment in testing capability, a 10-year-old, 350t rig has been upgraded with new servo controls and software, while a 55t tension-only machine, also in situ, completes the range of testing equipment available to the company’s engineering team.

Alfie Lee, operations director, said: “Improving our test facility was a significant undertaking on two levels. First, the equipment and software represented a substantial economic investment and, second, it was a logistical challenge. We had to make room for installation of the new machine, while relocating other equipment all within a tight timeframe in a busy manufacturing environment alongside our production and testing schedule.”

The MTS universal test machine, which provides testing capability verified by a third-party UKAS laboratory, arrived in the UK at the turn of the year. Local supplier Rapid Response Solutions provided a mini crane and oversaw lifting and moving operations related to installation and relocation of equipment.

David Ayling, director, said: “The MTS unit is a universal testing machine combined with customised tooling, creating a top-of-the-range rig tailored to the specific requirements of force measurement, load monitoring and suspended weighing load cell equipment.”Straightpoint engineers refer to the rigs within the new test centre by codename and choose SP6 (the upgraded 350t rig), SP7 (55t) or SP14 (the new rig) depending on capacity and type of test they need to complete. Engineers, who previously applied loads and controlled operations manually, now have access to closed-loop, servo-controlled testing ability when using SP6 and SP14.

Lee added: “We can now programme test routines, which means when we need to proof test a load cell and take the force to 50t three times, our engineers don’t have to apply, un-apply and reapply the load manually. Our throughput has been dramatically increased as a result.”

In addition to calibration, the new machine will support Roshan Divakaran, design engineer, and his team in ongoing research and development programmes.