Crosby|Straightpoint stock up to 500te Tension and Compression Load Cells as well as Loadshackles. SP can also produce cells for projects up to and over 2000te

From stock Crosby|SP supply up to 500te Tension and Compression Load Cells, and with a vertically integrated supply chain they can also supply larger capacities and custom orders.

When abnormal loads are in the upper ranges of what can lifted (in both overall weight and distribution of weight), close to the capacity of human ingenuity and technological capabilities; load monitoring cells are often used to help ensure the safety of the move.

This can also include cargo that is ‘Out-Of-Gauge’ (O.O.G), i.e. objects that do not fit within the constraints of a normal freight container, and also ‘Breakbulk’ that may have inconsistent load distribution from irregular internal configuration.

During the lifts, two types of wireless load cells are recommended to be used:

- Compression load cells

- Tension load cells

In situations like large steelworks, a wide variety of heavy and tandem lifting projects are carried out. These kinds of projects would include bespoke/unique castings with uneven weight distribution and come in huge units of weight. Compression cells, which can be wirelessly connected and used in conjunction with an ISO19901 compliant centre of gravity INSIGHT software package, will monitor the load at different points over the cast. This will allow the person managing the lift to discover where the heaviest sections are and adjust where the lifting points are.

At the same time, a Radiolink plus load cell(s) can be used as a ‘below-the-hook’ solution to monitor the weight as it is lifted. The load cell can also measure the load at different points to see where the centre of balance is.

Need a price? Contact our team

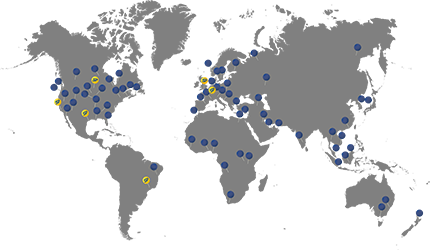

Experienced engineers/consultants that specialise in heavy lifts, who are employed by specialised freight forwarders, have huge responsibilities to achieve a successful and safe delivery with every project. Our load monitoring products our engineered to the highest standards, ensuring high reliability and accuracy, which are essential requirements for the co-ordinators managing these projects.

Examples of abnormal loads:

- Large steel works

- Heavy plant machinery

- Turbines

- Generators

- Distillation columns

- Modular accommodation – COG is not known due to different configurations inside