New Load Cell Test Machines for Straightpoint in UK and US

Straightpoint has installed two new loadcell test machines—a 100t unit at Hampshire, UK headquarters and a 55t system at the North American nerve center in Camarillo, California.

The MTS universal test machine, which arrived in the UK from the US manufacturer at the turn of the year, can test in compression and tension, giving Straightpoint the ability to test its entire range of load cells up to 100t.

The smaller 55t (or 120,000-lb.) tensile calibration machine completed a six-figure investment across both facilities in state-of-the-art equipment that can calibrate and re-calibrate load cells made by Straightpoint and other manufacturers.

Straightpoint director David Ayling said: “The MTS unit is the Rolls-Royce of calibration technology. It’s a universal testing machine combined with customised tooling, creating a top-of-the-range rig tailored to the specific requirements of force measurement, load monitoring and suspended weighing load cell equipment.”

The new MTS universal test machine joins a 10-year-old, manually operated, 350t test machine—the largest of its type known anywhere in Europe, Ayling claimed—on the workshop floor. Engineers, who previously applied loads and controlled the machine manually, now have access to a closed-loop, servo-controlled testing ability.

The new MTS universal test machine joins a 10-year-old, manually operated, 350t test machine—the largest of its type known anywhere in Europe, Ayling claimed—on the workshop floor. Engineers, who previously applied loads and controlled the machine manually, now have access to a closed-loop, servo-controlled testing ability. An additional investment in hydraulic drive systems and servo controls means the technological benefits of the new test rig can be applied to the older one.

Ayling said: “We can programme test routines, which means for instance when we need to proof test a loadcell and take the force to 50t three times our engineers don’t have to apply, un-apply and reapply the load manually. Our throughput is going to be dramatically increased as a result.”

In addition to calibration, the new machine will serve as a valuable tool as Roshan Divakaran, design engineer and Sarath Chandran, project engineer, lead ongoing research and development. ATEX and IECEx versions of Straightpoint’s most popular product, the Radiolink Plus wireless load cell, are now rolling off the production line and Ayling anticipates development of further enhancements to the range to be greatly aided by the new machine.

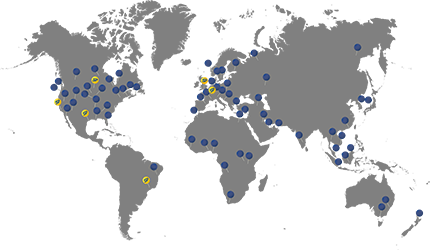

“The addition of the test machine in Camarillo is equally significant,” said John Molidor, general manager, Straightpoint Inc. “To give our customers, and the load cell user community beyond that, an in-house calibration service further expands our multifaceted offering to the myriad of marketplaces that are embracing such equipment.”

The MTS unit provides testing capability verified by a third-party UKAS laboratory, while its North American counterpart will test load cells calibrated and retraceable to ASTM E4.